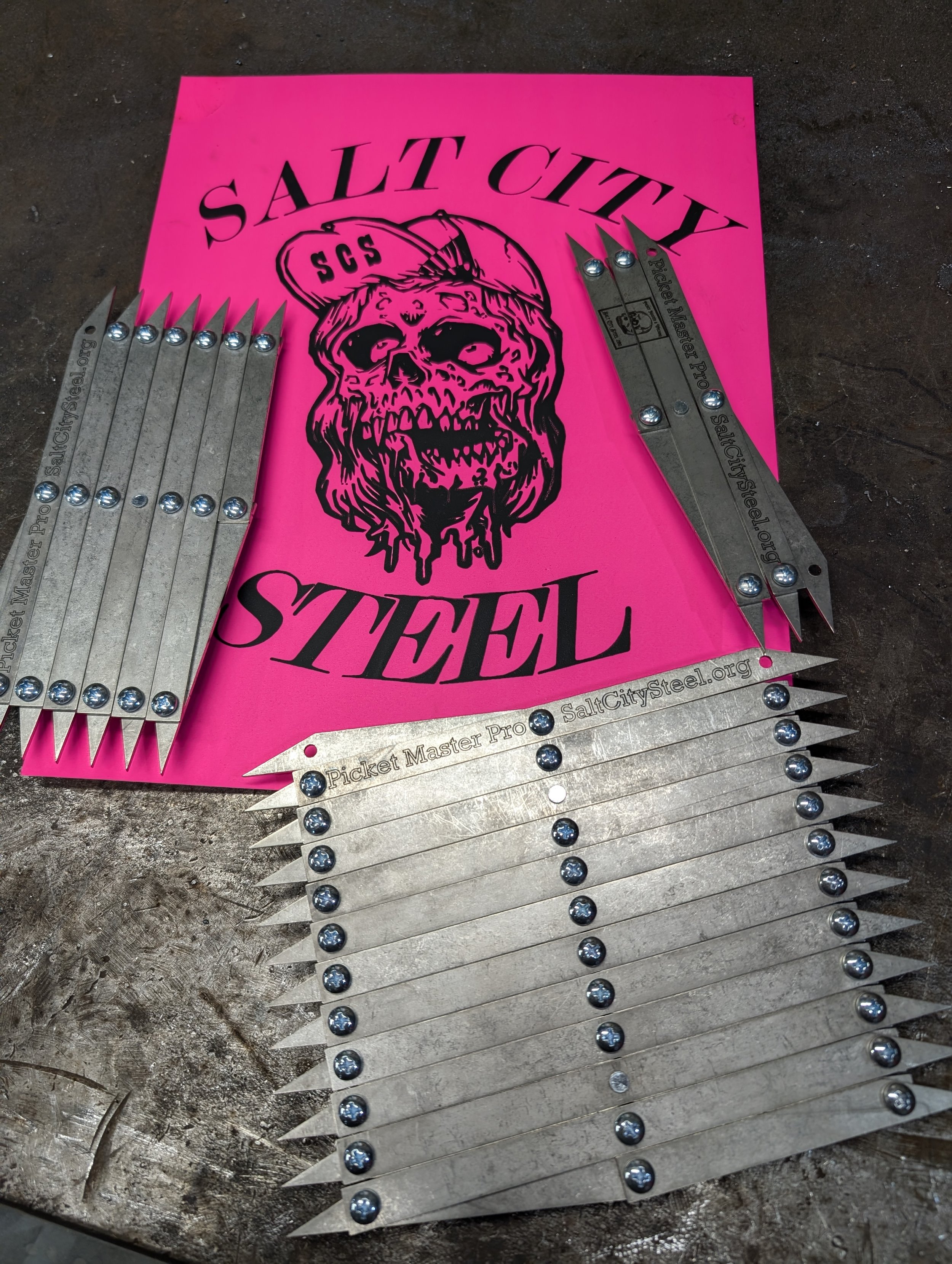

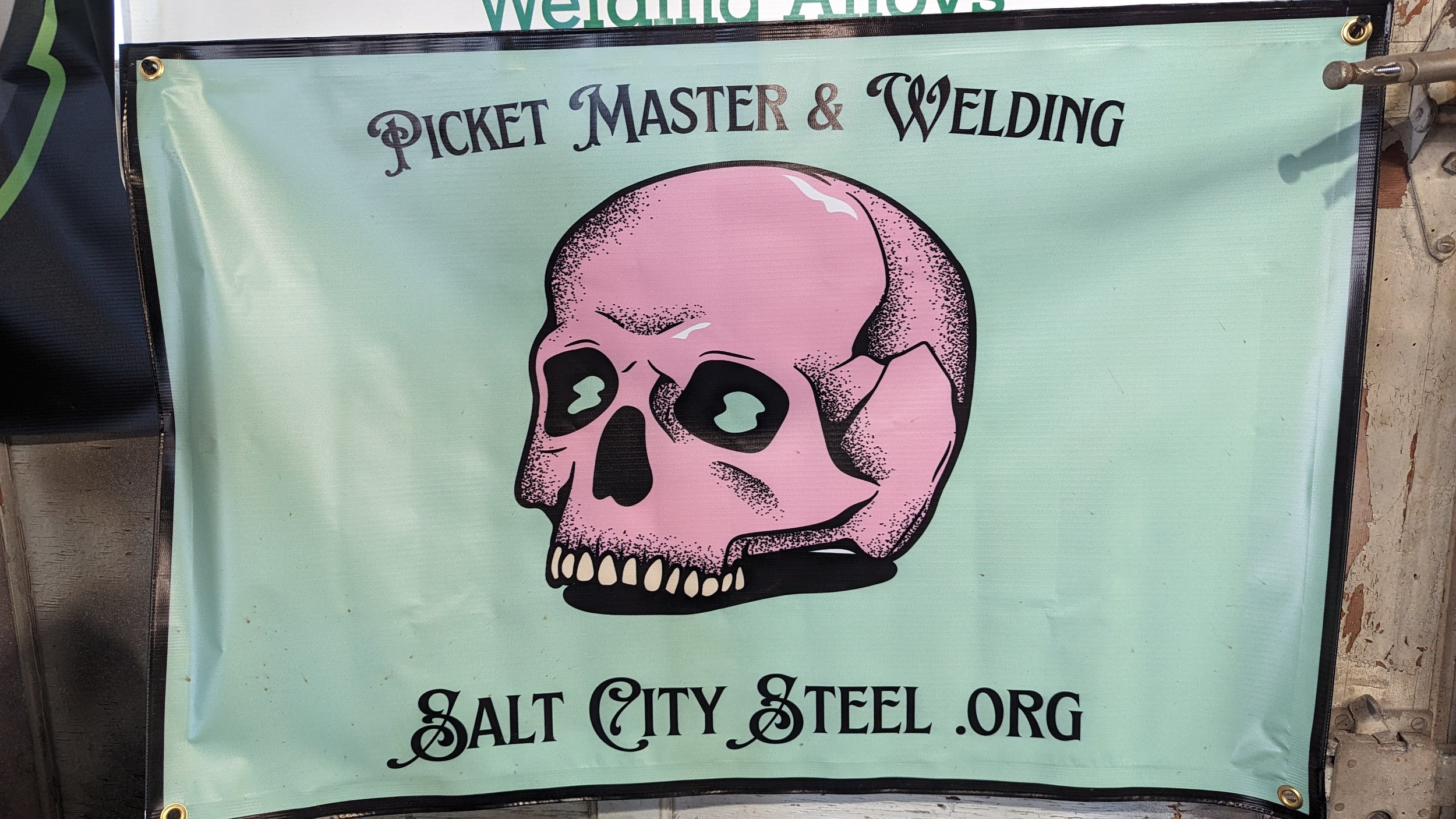

Salt City Steel Home of the PICKET MASTER ® PRO

Handmade in South Salt Lake, Utah USA

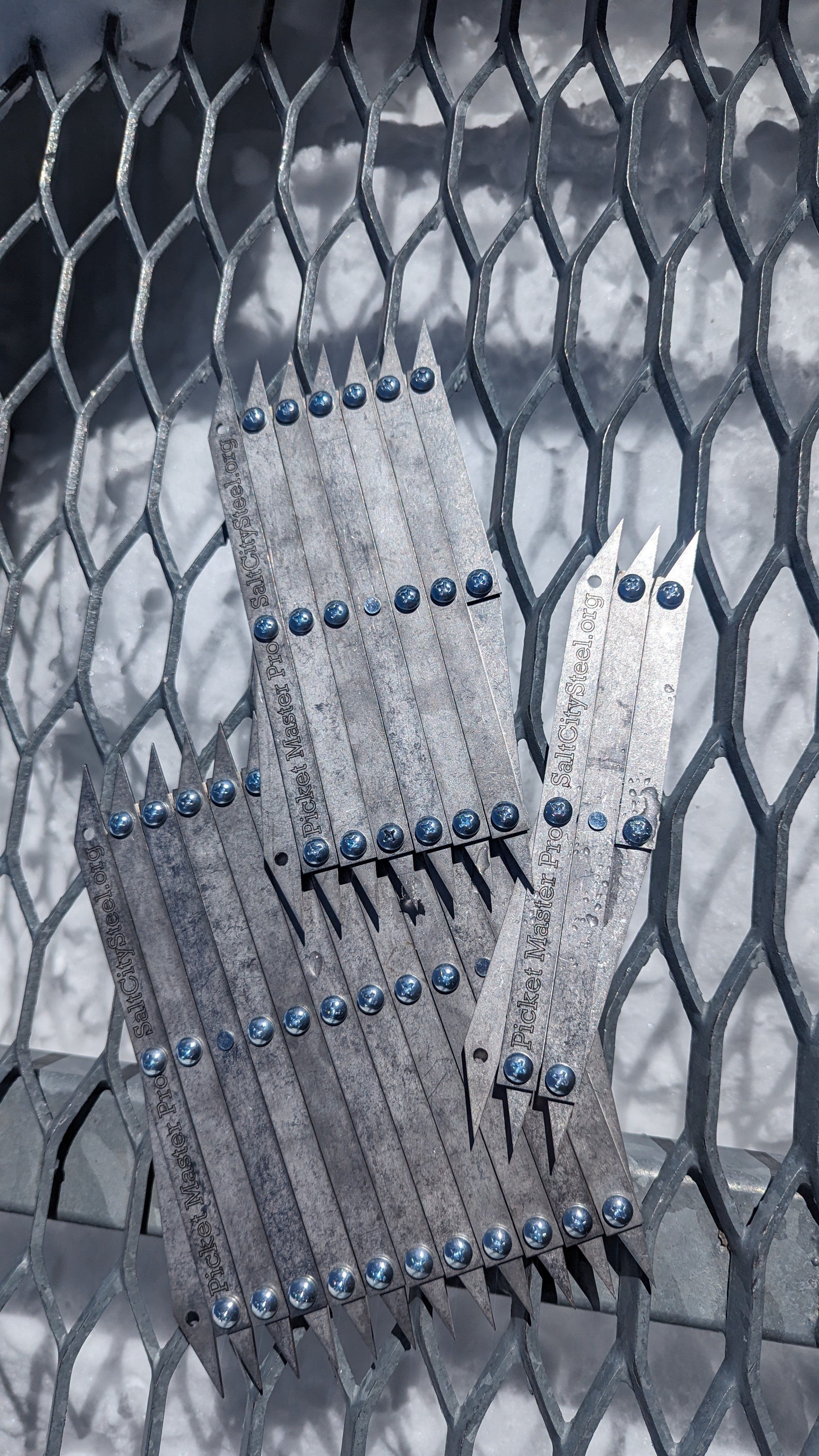

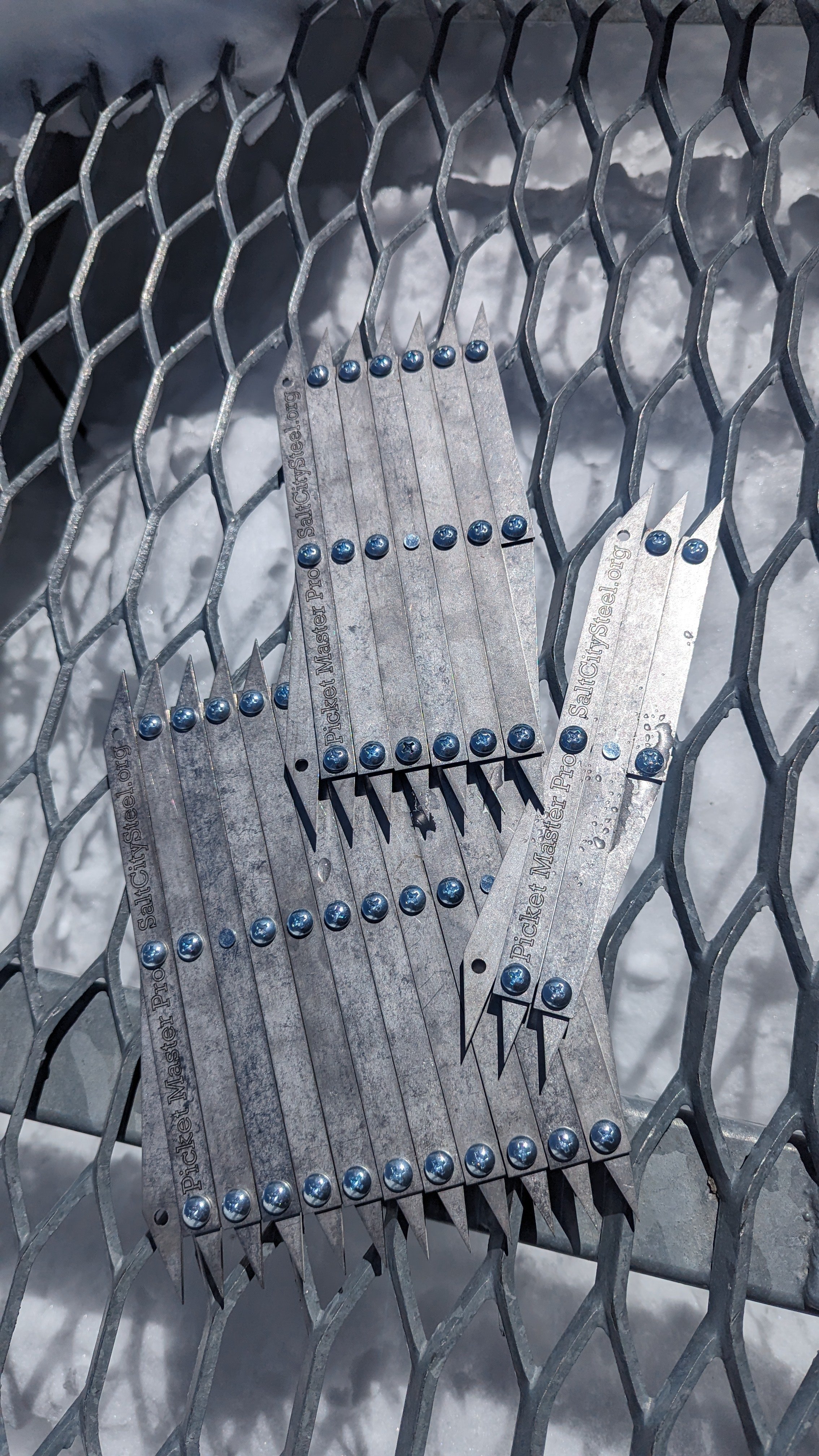

The Picket Master® Pro: Ensuring Quality and Authenticity

Salt City Steel is committed to providing durable, reliable tools for professionals and DIY enthusiasts. The Picket Master® Pro is a prime example, designed for precision and efficiency across various building projects.

This past year, we've identified unauthorized parties manufacturing and selling counterfeit versions of the Picket Master® Pro. These products infringe on our intellectual property and fail to meet the quality standards associated with Salt City Steel.

Purchasing counterfeit products can lead to:

Substandard Performance: Imitation tools lack the durability and precision of the genuine Picket Master® Pro, potentially compromising project quality and safety.

Financial Loss: Counterfeit products often fail prematurely, resulting in additional expenses for replacements.

Lack of Support: Salt City Steel does not provide warranty or support services for counterfeit products.

Legal Action

Salt City Steel is actively pursuing legal remedies to stop the production and sale of counterfeit Picket Master® Pro products. This involves taking all necessary steps to protect our intellectual property rights and ensure the integrity of the Picket Master® Pro.

Authentic Applications

The Picket Master® Pro is engineered for versatility across construction applications, including:

Fence Construction: Precise and efficient picket placement.

Decking: Consistent spacing and alignment of deck boards.

Railing Systems: Accurate installation of handrails and balusters.

Stair Construction: Uniform spacing for step placement.

General Construction: Versatile for any project requiring consistent spacing and precise measurements.

To guarantee you receive a genuine Picket Master® Pro, follow these guidelines:

Purchase Direct: Buy directly from the official Salt City Steel website: saltcitysteel.org.

Beware of Unrealistic Pricing: Exceptionally low prices are a red flag for counterfeit products.

Salt City Steel is dedicated to safeguarding the quality and authenticity of our products. By purchasing directly from us, you can be confident that you are investing in a genuine Picket Master® Pro that will meet your construction needs.

Stay Centered,

Salt City Steel

FAQ

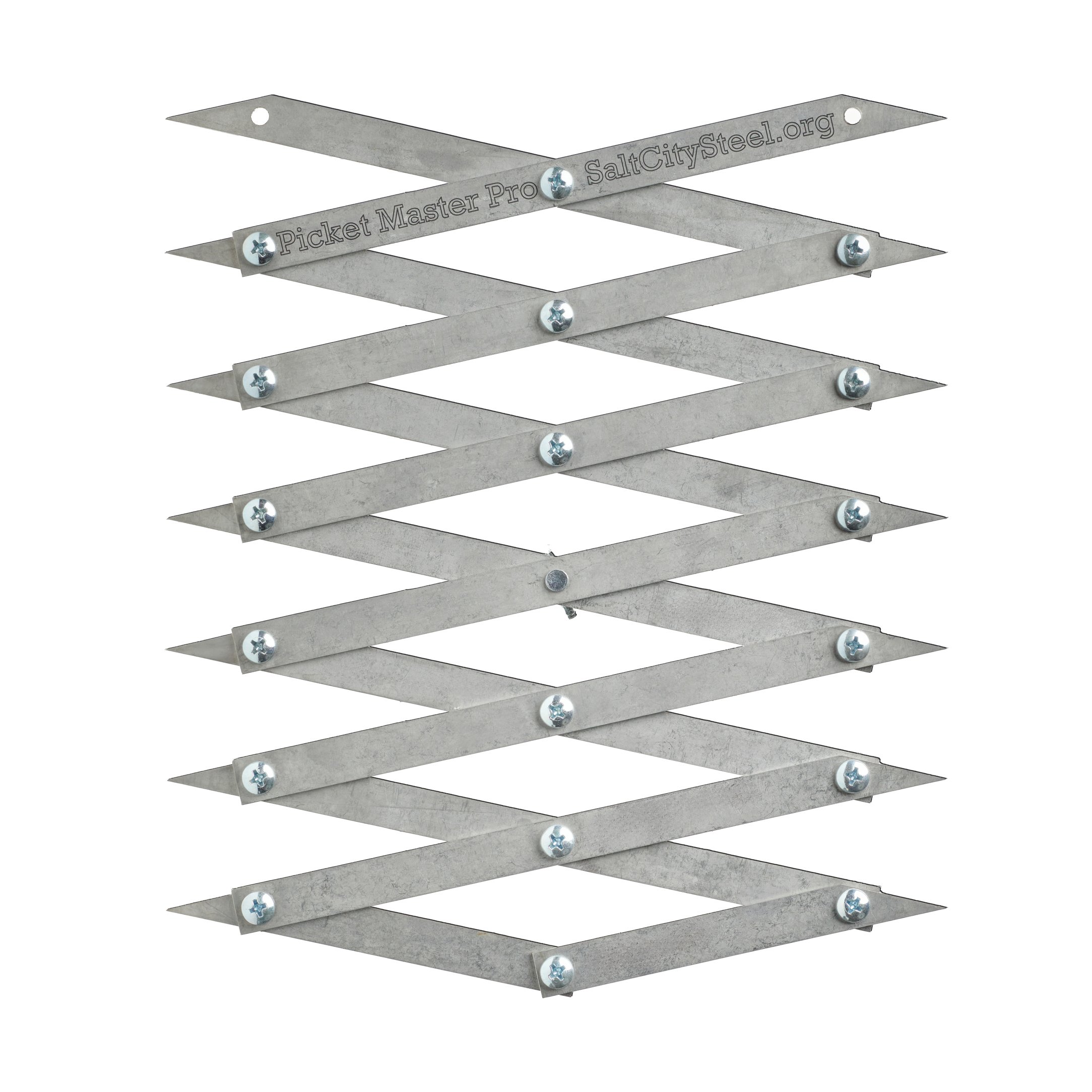

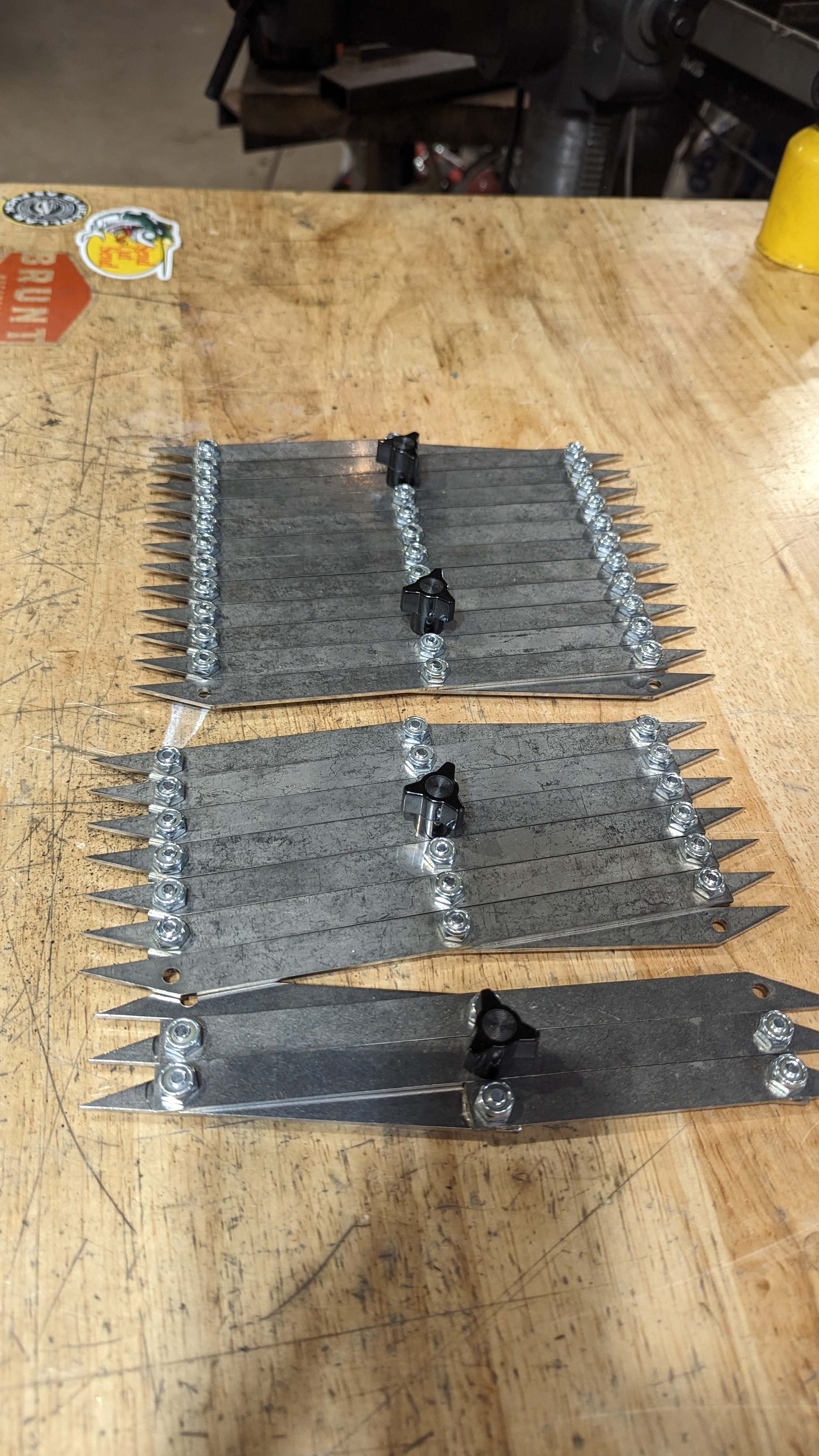

What is the Picket Master® Pro?

It's a professional-grade, equal-spacing layout tool that eliminates math and manual measuring for pickets, balusters, and repetitive marks, turning a complex layout job into a fast, accurate mark-and-go task.

What is the simplest way to use the tool?

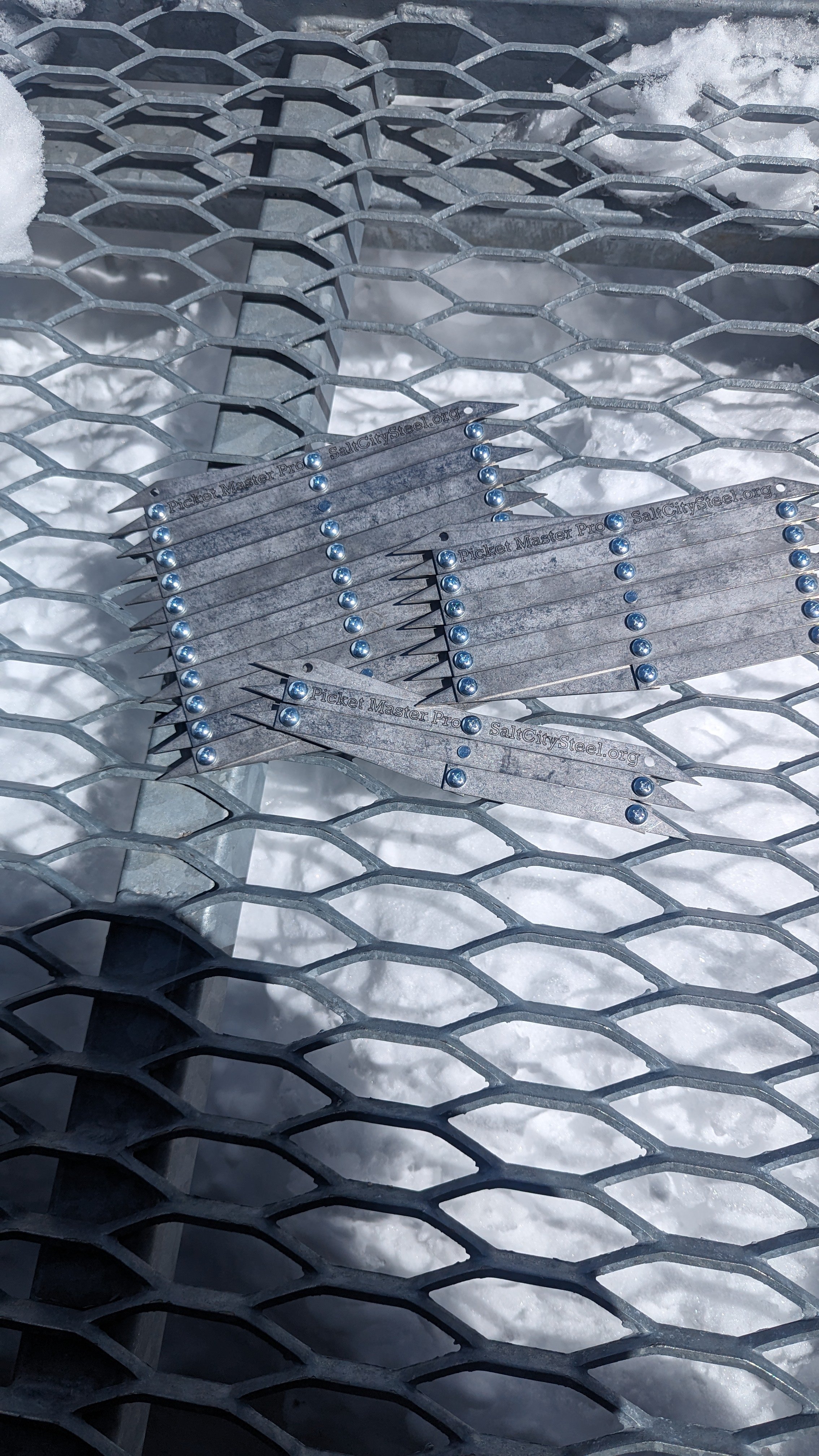

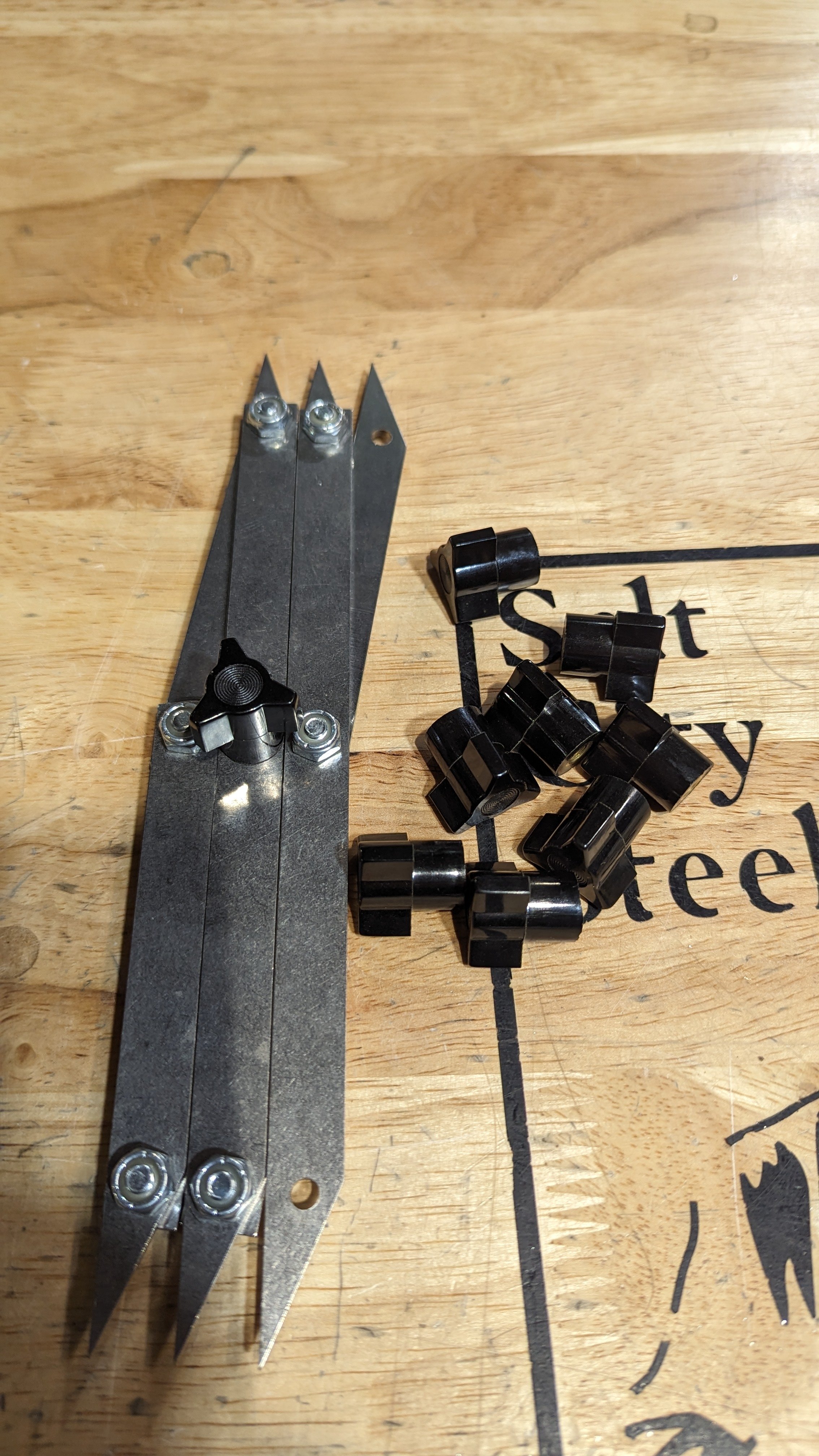

Adjust the tool to your desired distance, lock the thumb screws down tight, and mark every point. Every space will be identical.

Does it work with Metric measurements?

Yes. The tool's function is division, not explicit measurement. You set the desired physical gap (Metric or Imperial) between the points, lock it, and it divides the space perfectly.

Which model should I buy: 12-Point, 7-Point, or the 3-Point?

For the most versatility, buy The Full Monty Bundle (all three). The 12-Point handles the largest jobs, and the 3-Point is a dedicated center-finding tool.

How does the Picket Master® Pro eliminate math?

It uses a mechanical linkage design that automatically divides the distance you set into equal segments. You lock the screws, and you've locked in the perfect, precise spacing—no calculators or complex fractions needed.

Does this tool save time and prevent material waste?

Yes. Your layout is perfect the first time, preventing the need to recut or re-weld misaligned pieces. Less waste directly leads to higher efficiency and increased profit.

Why is my spacing inconsistent when I open the tool?

The high-precision linkage must be opened using two hands, pulling on both ends simultaneously. Trying to open it one-handed will cause the mechanism to bind or skew slightly.

Do I need to account for the picket material width?

Yes, absolutely. The tool marks the center of the space between pickets. You must subtract the material width (e.g., 1/2 inch bar) from your total run before setting your spacing on the tool.

How do I handle very large railings (longer than the tool)?

Work in halves or sections. Lay out one half of the panel, then move the tool and mark the next section, using the calculated center point to ensure the entire length is consistent.

How does the tool help me pass the final inspection?

Building codes require strict, consistent spacing (e.g., the 4-inch rule). The Picket Master® Pro eliminates the risk of a single point being out of compliance, saving you costly re-work and ensuring a smooth final inspection.

What is the minimum/maximum spacing?

The 12-Point model can be set from as small as 1/2 inch up to approximately 6 1/2 inches between points, covering all common building code requirements.

Why is the picket master® Pro better than a cheaper expanding ruler?

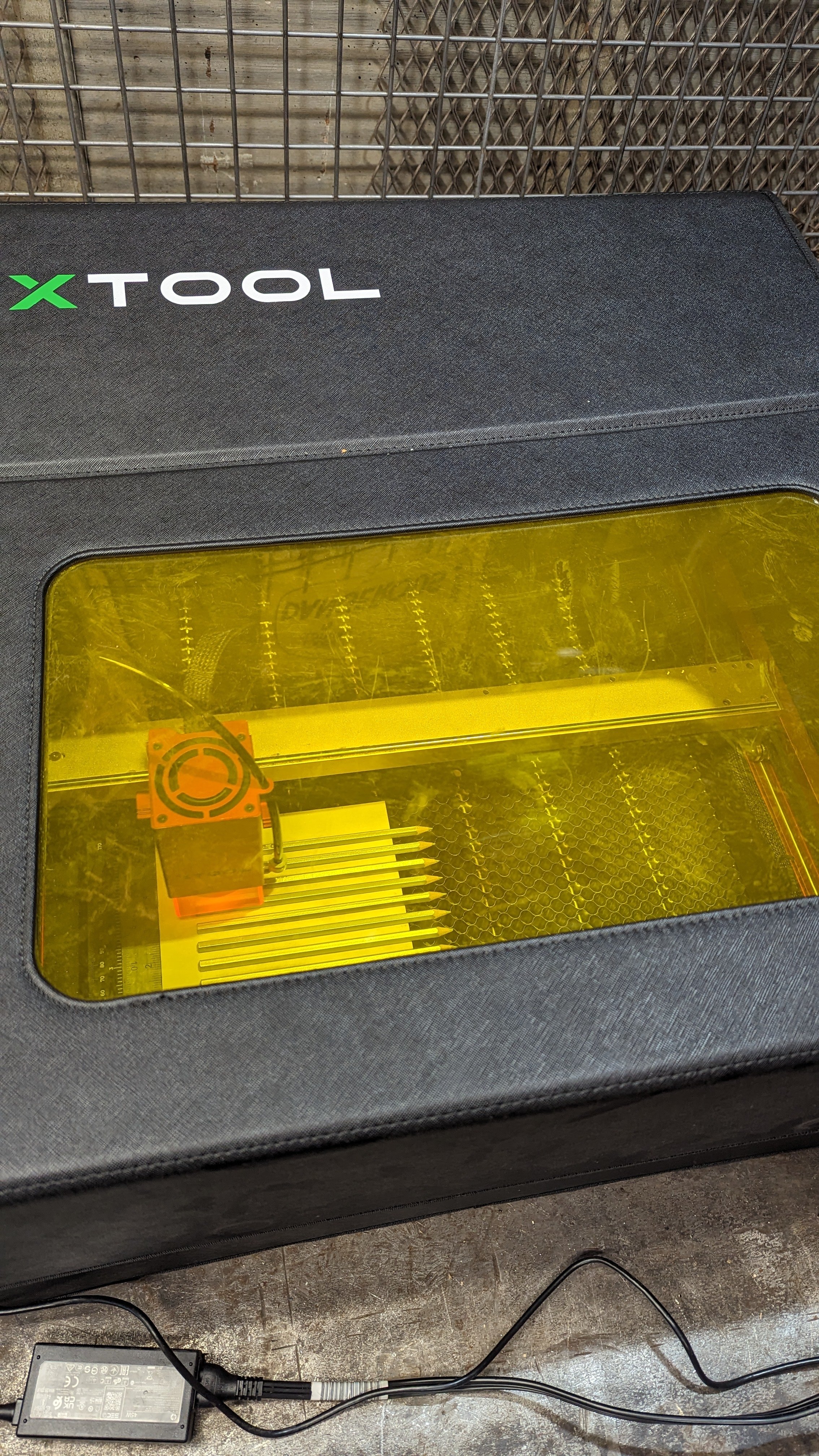

Unlike cheap gauges with riveted, warping linkages, the Picket Master® Pro is crafted from laser-cut stainless steel. It’s engineered to lock down rigidly, ensuring reliable, code-compliant precision on every mark.

How do I handle railings that don't divide evenly?

Find the true center of the rail first and mark outward from there. This ensures any minor spacing variance is split equally between the two ends, keeping the final product visually balanced.

Can I use the tool for non-railing projects?

Absolutely. It's an equal spacing layout tool trusted by welders, woodworkers, and DIYers for anything requiring repetition or finding the center.

Where is the Picket Master® Pro made?

Every tool is meticulously handcrafted in South Salt Lake, Utah, USA, ensuring high-quality, American-made craftsmanship.

Can I use the Picket Master® Pro on wood or aluminum?

Yes, it works flawlessly on wood, metal, and plastic. For softer materials, use a sharp pencil or fine marker to dot the marks made by the tool's precision points.

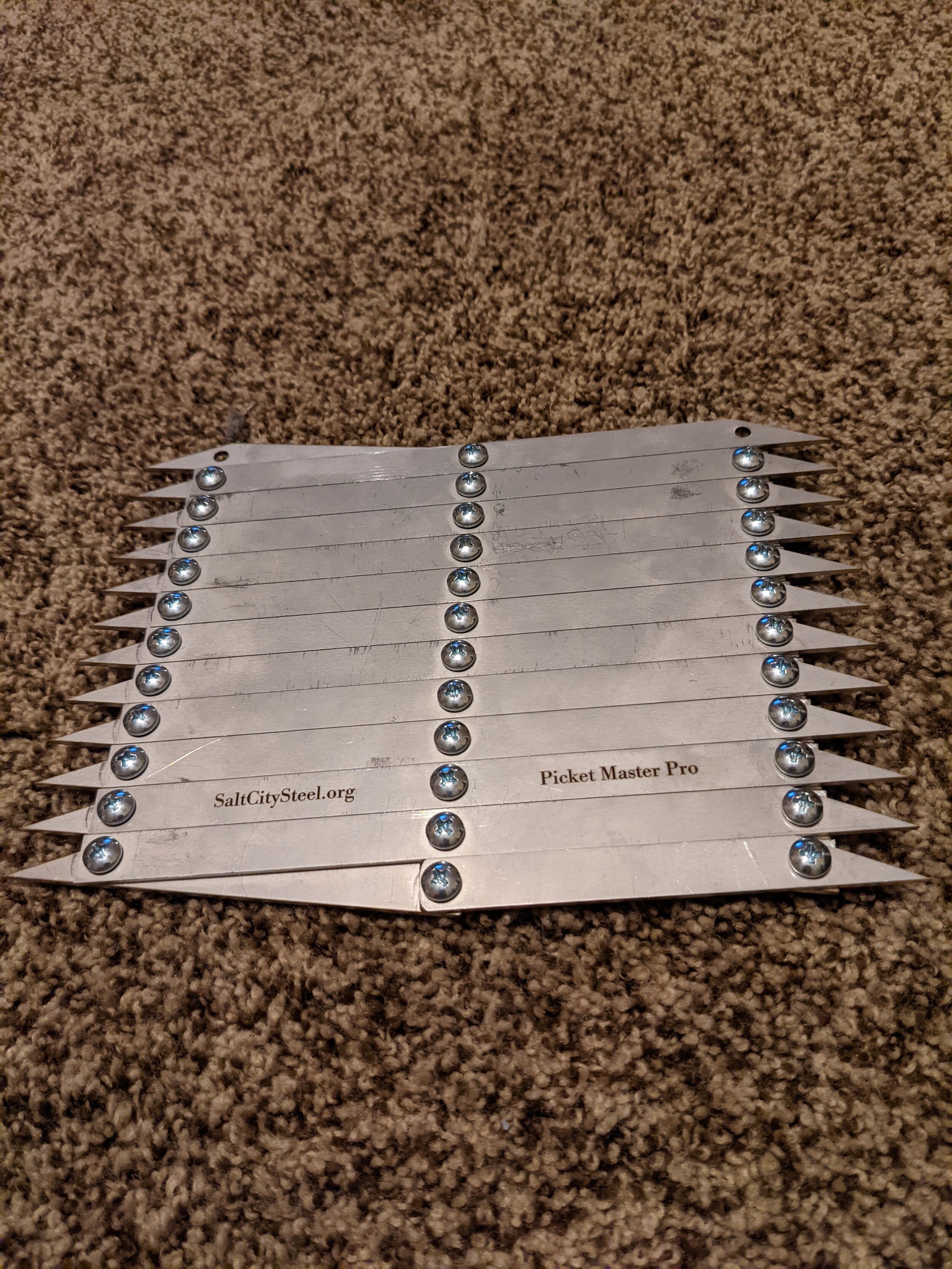

What is the recommended maintenance?

Minimal maintenance is required. We recommend an occasional cleaning with a light solvent and applying a single drop of light machine oil to the pivot points to keep the action smooth.

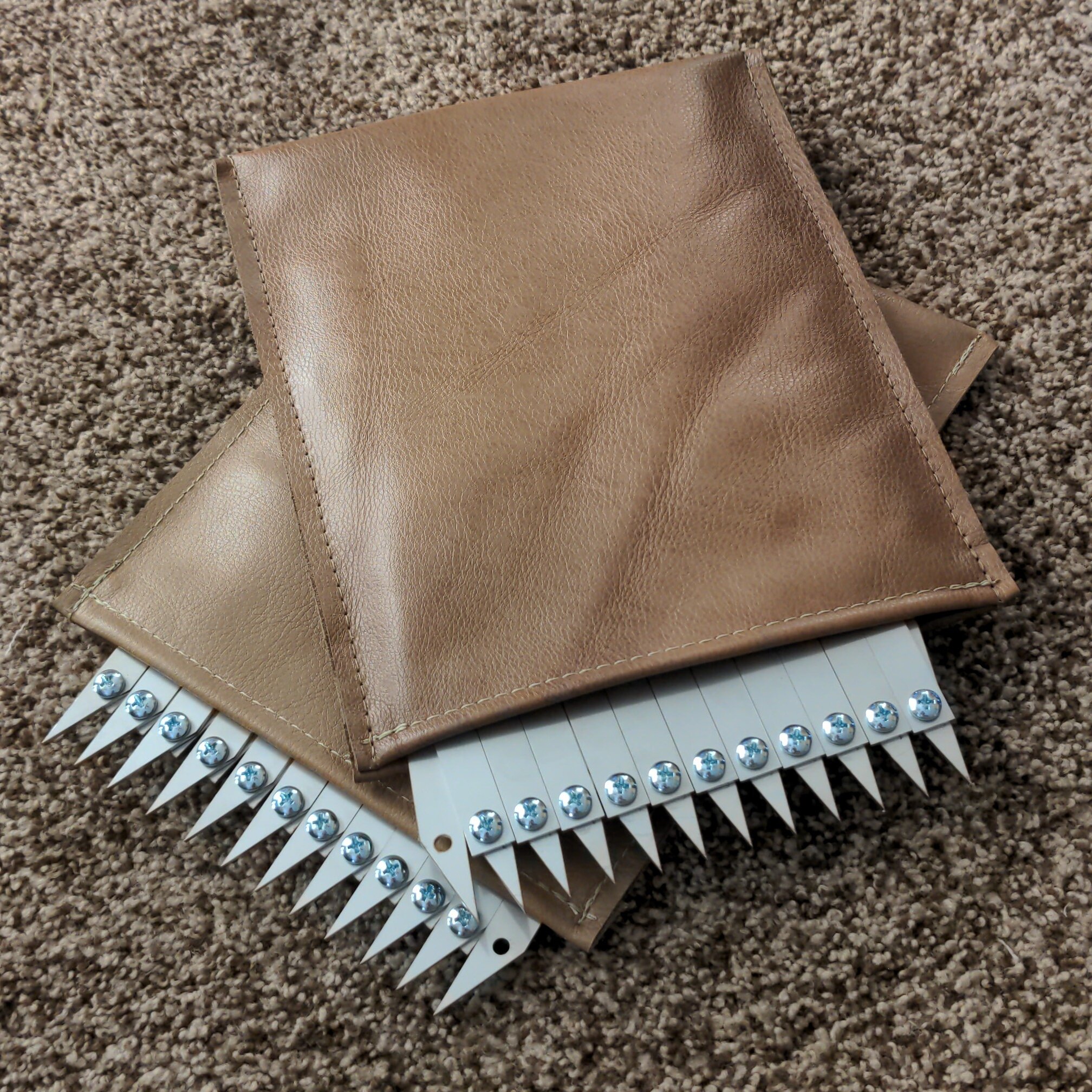

How should I store the tool?

Always collapse the tool and use the custom-made protective case it ships with. This protects the precision points from being damaged by other tools in your box. We also offer kaizen CNC cut foam inserts for Milwaukee pack-out cases.

What about international shipping, duties, and taxes?

We ship worldwide, but the international purchaser is responsible for all additional costs, including local duties, import taxes, customs clearance fees, and VAT required by the destination country.

Can I get bigger wing nuts or other parts if they get damaged?

Yes. We sell extra-large thumb nuts and other parts directly through our website. The tool is designed to be fully repairable, ensuring that a simple bent tip doesn't put your tool out of commission.

What are the limitations for custom laser engraving?

We can engrave logos or text onto the stainless steel. The engraving is typically limited to the blades that don't have existing logos or markings.

Is there any professional training or a user manual available for advanced techniques?

Yes. While the tool is intuitive, we offer tutorial videos on our website and social media.

Is the Picket Master® Pro durable enough for a busy fabrication shop?

Yes. It is constructed from laser-cut stainless steel, making it highly resistant to corrosion, shop chemicals, weld spatter, and daily abuse. It's built to be a reliable, lifelong tool.

Will this tool help me win arguments with my coworker about who gets to do the layout?

Absolutely. The Picket Master® Pro is so fast and accurate that it eliminates all arguments. Instead of fighting over the calculator and tape measure, you’ll just hear: “Hey, thanks for leaving me the easy job. I’m already done.”